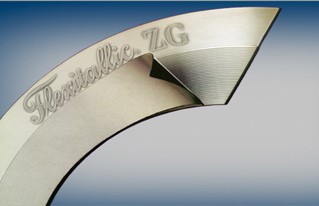

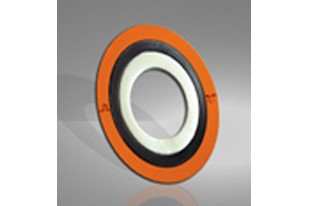

Incredibly robust and resilient, metal-wound Change heat exchanger gasket is designed to deliver the most dynamic seal ever. Manufactured with proprietary equipment, using a 5-times thicker metal spiral and a unique laser welding process that penetrates completely through. So it requires no inner or outer ring, and is as easy to handle and install as a double-jacketed gasket. Best of all, it’s proven to perform without fail at least 60% longer than any other heat exchanger gasket, spiral wound, double jacketed, CMG, or Kammprofile, and that is a game changer.