- 首页

- 公司介绍

-

代理品牌

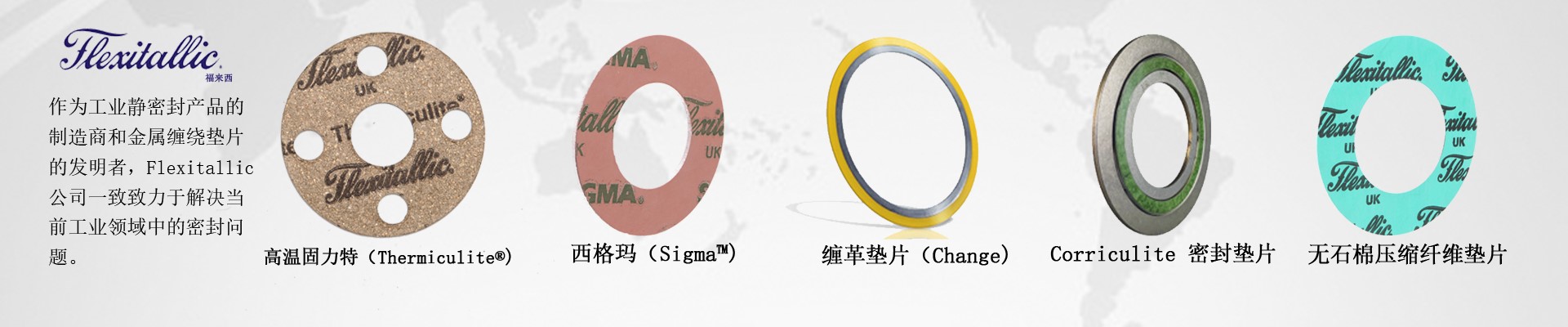

- Flexitallic福来西

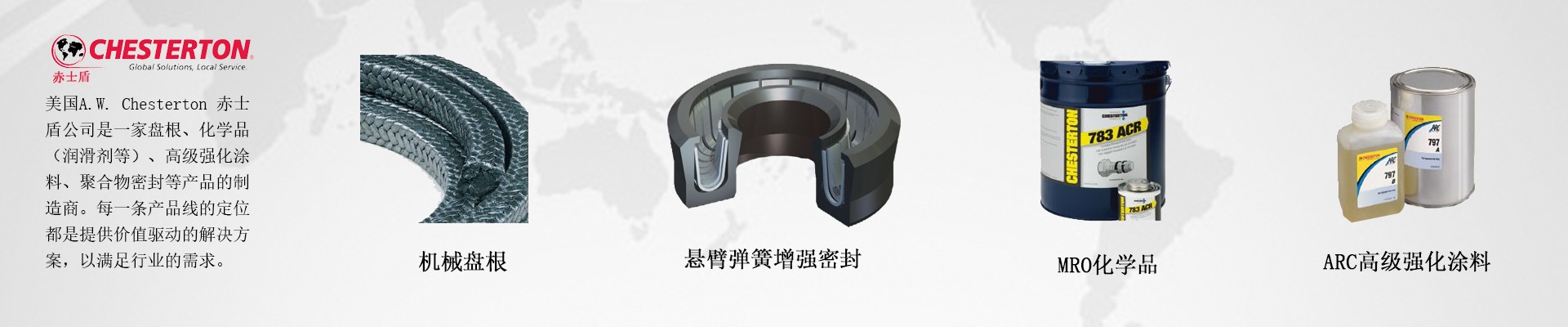

- Chesterton赤士盾

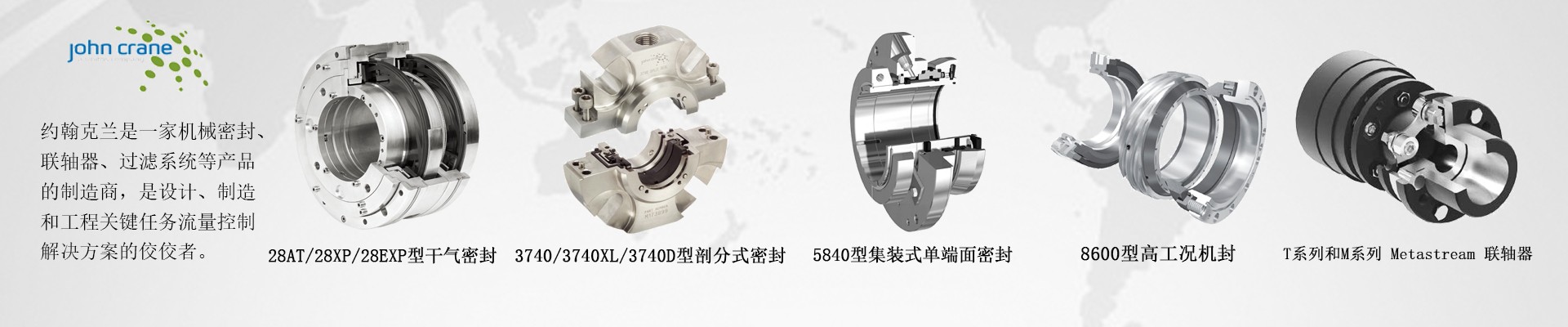

- John Crane约翰克兰

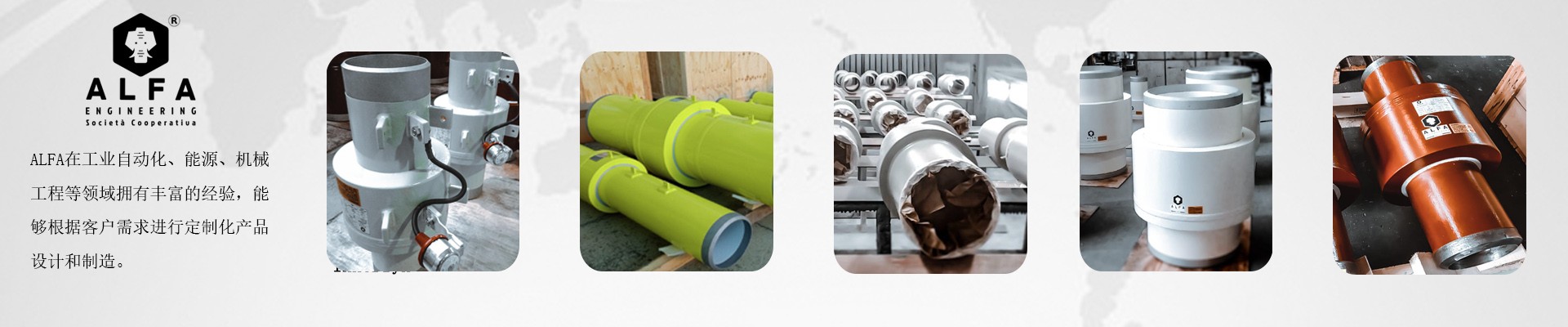

- ALFA

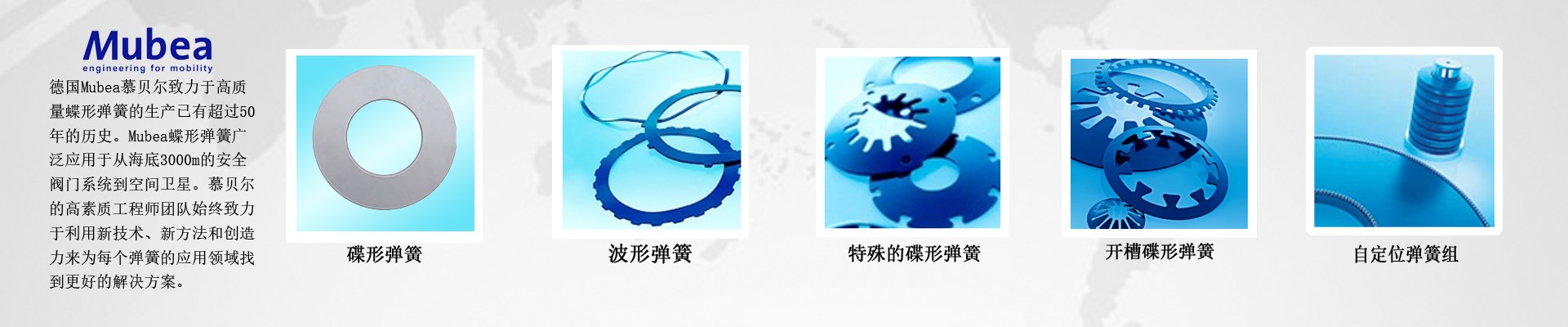

- Mubea慕贝尔

-

APS

- CASING SPACERS & END SEALS

- Innerlynx®

- Flange Isolating Gasket Kits

- Flange Band Protectors

- UBolt-Cote® Pipe Supports

- IsoJoint

- Meter Service Fitting

- Safety Spray Shields

- DuoCon Centralizers

- Radolid® Bolt and Nut Protection Caps

- Wall Sleeves

- Hammer & Pile Cushion Pads

- Inspect-A-Lift®

- Raq-Gard®

- Maloney/Foreman Nite Caps

- Katy 弹簧

- 自有品牌

- 资质&荣誉

- 技术&支持

- 新闻资讯

- 联系我们

- 中文

- EN

ALFA Monolithic Isolating Joints

ALFA's Technical Dept. creates the engineering of each project according to customers' requirements and after analysing the specs received, it suggests the best solutions in compliance with the corresponding norms.

产品特性

SIZES:

from ½” to 80” DN

PRESSURE CLASSES:

ANSI: # 150, # 300, # 600, # 900, # 1500, # 2500

API: # 10.000

MATERIALS:

Carbon steel, duplex and super duplex, stainless steel, cladded

NORMS:

ASTM, DIN, ASME, DNV, API, ISO, EN, NORSOK, NACE

INSULATOR:

Nema G11 class H, with best properties on the market.

O-RINGS:

Sealing system in order to grant the seal of the joints: Double o'rings of different materials according to fluid and temperature, including AED type.

WARRANTY:

Joints have a standard warranty of 24 months after shipment.

WHY TO USE MONOLITHIC ISOLATING JOINTS

The use of Monolithic Isolating Joints is highly recommended to mitigate risks of corrosion and to grant more efficient Cathodic Protection System.

Welded on the pipeline MIJs protect all the line blocking the flow of electric currents, which are the main cause of corrosion and leakages.

Joints are used in order to:

• safeguard the pipeline from corrosion and corrosion-related failures

• isolate the pipeline and to ensure that stray/earthing electricity currents do not cause increased corrosion

• limit spread and the related high cost of traditional cathodic protection system

• electrically “split up” long pipeline into distinctive cathodic protection system

• avoid pipeline shutdown because of failure, replacement or leakage

• increase life time of the pipeline

• decrease overall project life cycle cost (no recurring upkeeps)

Cathodic protection is the main way to prevent metal against corrosion, for this reason isolating joints are essential in an efficient cathodic protection system and ensure the long life of the pipeline.

应用

ALFA's joints are designed project-based for sweet or sour service and for above or below ground installation, plus sub-sea installation. ALFA had ISO 9001:2015 and PED certified.